Plywood and MDF are two common types of engineered wood, widely used in furniture manufacturing and architectural decoration. Below is a detailed comparison of their material composition, price, and advantages/disadvantages.

Material Composition

- Plywood: Constructed by laminating multiple thin wood veneers together with adhesive under high temperature and pressure. The grain direction of adjacent layers is perpendicular, enhancing the board’s stability and strength. Common wood species include birch, poplar, and eucalyptus.

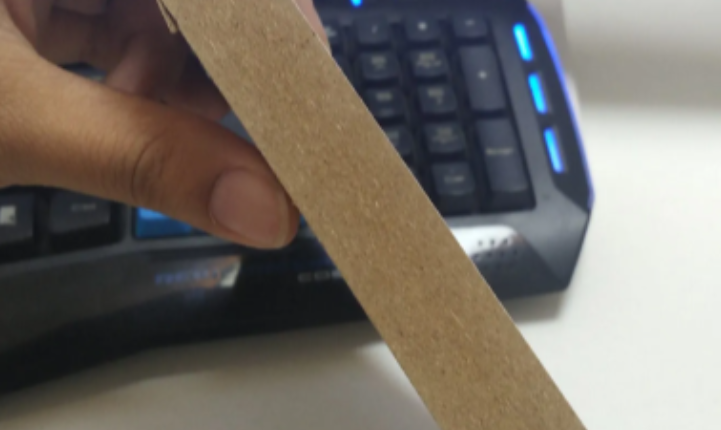

- MDF: An engineered wood product made by wood fibers or plant fibers under high temperature and pressure. Its thickness ranges from 3 to 30 mm.

Price

- Plywood: Relatively expensive. Waterproof plywood commands an even higher price.

- MDF: Relatively inexpensive, making it a cost-effective choice.

Advantages and Disadvantages

Advantages of Plywood:

- Good Moisture Resistance: Suitable for humid environments such as kitchen cabinets and bathroom vanities.

- Good Structural Stability: Resistant to warping and deformation, with strong load-bearing capacity.

- Easy to Process: Convenient for cutting and shaping.

Disadvantages of Plywood:

- Difficulty Controlling Formaldehyde Levels: The adhesives used may result in unstable environmental performance.

- Poor Resistance to Changes: Sensitive to changes in temperature and humidity.

Advantages of MDF:

- Smooth Surface: Ideal for painting, veneering, and finishes.

- Uniform Density: Good stability, resistant to warping.

- Easy to Process: Supports various machining methods, including cutting, milling, and drilling.

- Strong Shaping Ability: Suitable for creating complex shapes and designs.

Disadvantages of MDF:

Environmental Concerns: Requires selecting products that meet environmental standards to control formaldehyde emissions.

Poor Moisture Resistance: Prone to water absorption, swelling, and deformation when exposed to moisture; not suitable for humid environments.

Relatively Weaker Load-Bearing Capacity: Slightly inferior to plywood in terms of load-bearing strength.

In summary, plywood and MDF each have distinct characteristics and suitable applications. The choice should be based on specific needs, considering factors such as moisture resistance, load-bearing capacity, processing difficulty, and environmental requirements.